EFFECT OF REPEATED FIRING OF PORCELAIN FUSED TO METAL ON PORCELAIN COLOR CHANGE

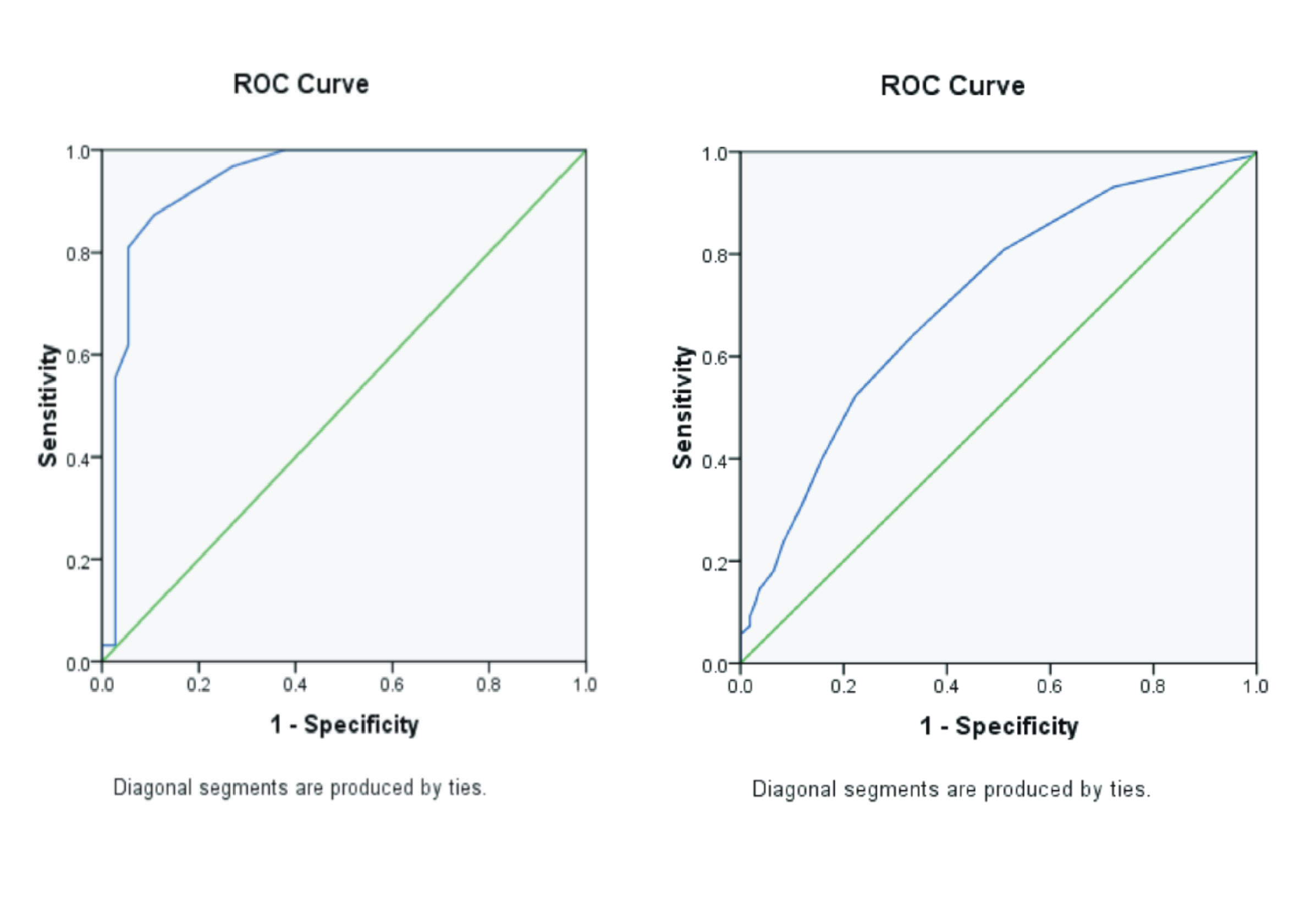

Downloads

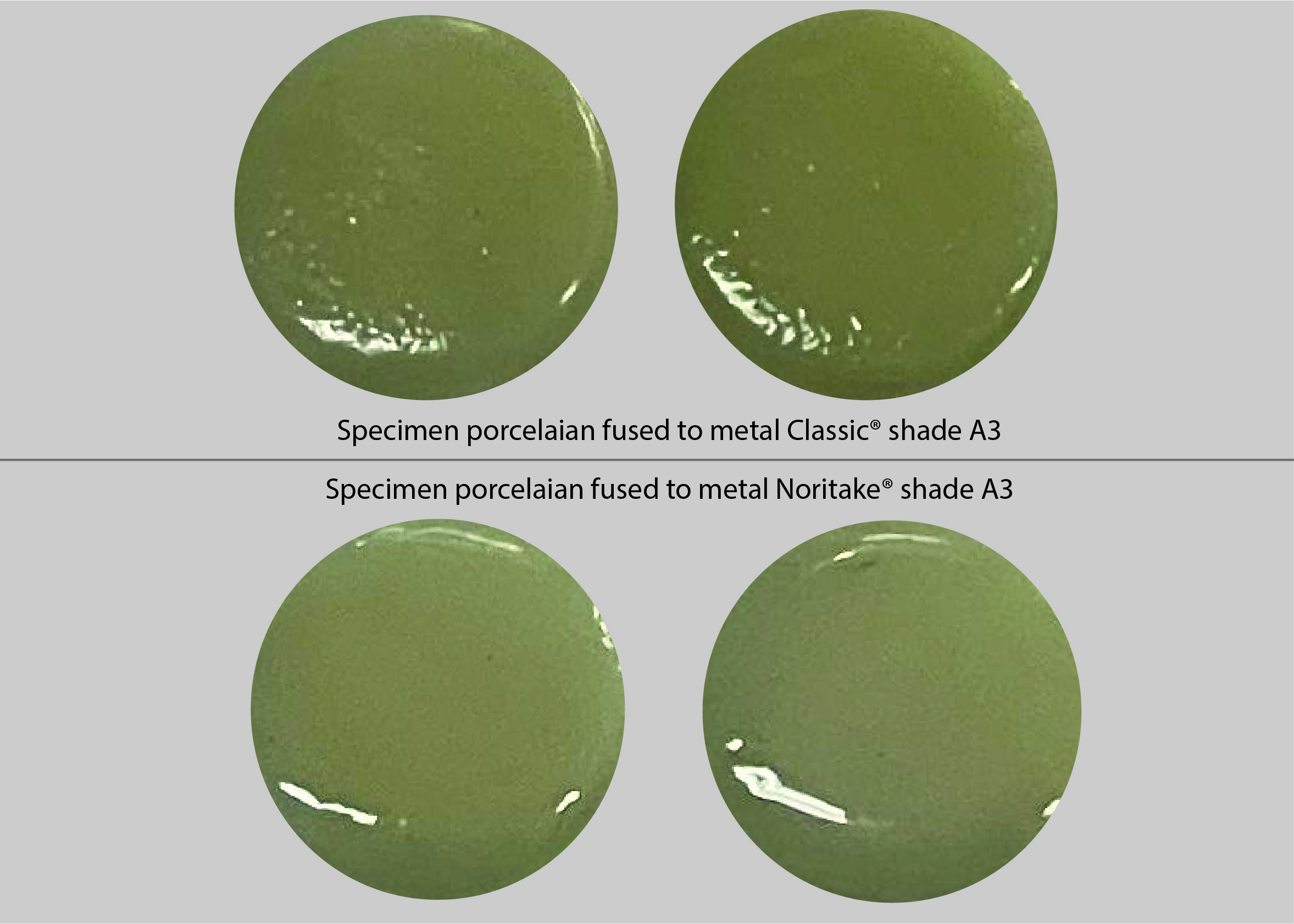

Background: The color of the porcelain surface is the main criterion for achieving perfect aesthetics. A factor that influences the color is the amount of firing of the porcelain. Purpose: To determine the color change of porcelain after repeated firing four times. Method: The research specimens consisted of 6 metals coated with Classic porcelain and 6 metals coated with Noritake porcelain and were subjected to four firing stages, then each stage was fired four times. The color change value was measured using VITA Easyshade. Statistical analysis using ANOVA. Result: The Classic and Noritake groups experienced a significant increase in color change from 1st to 2nd burning and from 1st to 3rd burning with a p-value < 0.05. There is a significant difference in the color change value based on the repetition of porcelain firing with a significance value of 0.000 < 0.05. There is a significant difference in the color change value based on porcelain products with a significant value of 0.020 < 0.05. There is no significant effect between repeated firing on porcelain and porcelain products in affecting the color change value with a significance value of 0.143 > 0.05. Conclusion: Both product groups experienced an increase in color change from firing 1st to 2nd and from firing 1st to 3rd. There was no increase in color change from firing 2nd to firing 3rd. There are significant differences in color change values based on porcelain products and there is no significant effect between repeated firing on porcelain and porcelain products on affecting color change values.

Afkhami, F., Elahy, S., Nahavandi, A.M., Kharazifard, M.J., Sooratgar, A., 2019. Discoloration of Teeth due to Different Intracanal Medicaments. Restorative Dentistry & Endodontics Vol. 44(1), Pp. e10.

Alfarisa, T., 2020. Estetika Restorasi Porcelain Fused to Metal pada Kasus Crossbite Anterior (Thesis). Universitas Airlangga.

Alnassar, T.M., 2022. Influence of Multiple Firings on The Color Stability and Surface Roughness of Gingival Pink Feldspathic Ceramic. Coatings Vol. 12(12), Pp. 1870.

Amir Rad, F.A., Succaria, F.G., Morgano, S.M., 2015. Fracture Resistance of Porcelain Veneered Zirconia Crowns with Exposed Lingual Zirconia for Anterior Teeth after Thermal Cycling: An in Vitro Study. Saudi Dental Journal. Vol. 27(2), Pp. 63-69.

Barnard, R.G., 2021. Sorption and Solubility of Denture Base Acrylic: A Comparative Surface Treatment Study (Thesis). Cape Peninsula University of Technology, Cape Town, South Africa.

Demirel, M., Tunçdemir, A., 2023. The Effect of Repeated Firings on The Color Change of Metal Based Ceramics Produced with Different Techniques. Necmettin Erbakan Universitesi Dis Hekimligi Dergisi ((Necmettin Erbakan University Dental Journal), Necmettin Erbakan Pp. 67-74.

Elbasuny, I.W., Shakal, M., Seddik, M., Elshahawy, W., 2021. The Effect of Repeating Firing Cycle on The Shade of Porcelain Fused to Metal, All-Ceramic and Zircona Restorations. Tanta Dental Journal Vol. 18(1), Pp. 20.

Gunawan, J., Takarini, V., Hasratiningsih, Z., 2017. Performa Porselen Fusi Logan dan Porselen Penuh. Jurnal Kedokteran Gigi Universitas Padjadjaran Vol. 29(3), Pp. 209-212.

Hidayatin, I., Indiani, S.R., Ratwita, R.D.F., 2019. Coping Manufactured Technique of Spinell Slip Cast All Ceramic by Conventional Methode and CAD/CAM. Journal of Vocational Health Studies Vol. 3(1), Pp. 32-36.

Katada, H., Inokoshi, M., Kamijo, S., Liu, H., Xu, K., Kawashita, M., Yokoi, T., Shimabukuro, M., Minakuchi, S., 2024. Effects of Multiple Firings on The Translucency, Crystalline Phase, and Mechanical Strength of Highly Translucent Zirconia. Dental Materials Journal Vol. 43(2), Pp. 294-302.

Kumar, K.R., Sukumar, R., Reddy, L.P., Pavan, T., Kiran, G., Navya, R., 2017. The Effect of Repeated Firing on The Color of Ceramic System with Two Different Veneering Porcelain Shades.

Laoh, M.H., Siagian, K.V., Ticoalu, S.H.R., 2016. Status Gingiva pada Pasien Pengguna Gigi Tiruan Cekat di RSGM PSPDG Fakultas Kedokteran Universitas Sam Ratulangi Manado. e-GiGi Vol. 4(2), Pp. 196-201.

Manappallil, J.J., 2015. Basic Dental Materials, 4th edn. JP Medical Ltd.

Mohamed, S., Ahmed, A., Mekkawi, W., 2020. Effect of Repeated Firings on The Color Change and Surface Roughness of Two All-ceramic Systems. Al-Azhar Dental Journal for Girls Vol. 7(1), Pp. 345-354.

Nuraeni, O., Fitriyani, F., 2023. Sistem Pakar Diagnosa Kondisi Gigi Tiruan menggunakan Metode Naïve Bayes Classifier. JIKA (Jurnal Informatika) Vol. 7(1),Pp. 79-88.

Özdemir, H., Duymus, Z.Y., 2019. The Effect of Laboratory Procedures and Repeated-Glazing on Color of Metal-Ceramic Restoration. Contemporary Clinical DentistryVol. 10(2), Pp. 239-242.

Rosenstiel, S.F., Land, M.F., Fujimoto, J., 2006. Contemporary Fixed Prosthodontics, 4th edn. Elsevier Health Sciences.

Siagian, K.V., 2016. Kehilangan Sebagian Gigi pada Rongga Mulut. e-CliniC Vol. 4(1), Pp. 1-6

Swapna, B., Shalini, K., Sreeramulu, B., 2018. Effect of Repeated Firings on The Color of Porcelain: An in Vitro Study. Indian Journal of Dental Advancements. Vol. 10(1), Pp. 21-29.

Tabatabaian, F., Khodaei, M.H., Namdari, M., Mahshid, M., 2016. Effect of Cement Type on The Color Attributes of A Zirconia Ceramic. The Journal of Advanced Prosthodontics Vol. 8(6), Pp. 449.

Ueda, N., Takagaki, T., Nikaido, T., Takahashi, R., Ikeda, M., Tagami, J., 2021. The Effect of Different Ceramic Surface Treatments on The Repair Bond Strength of Resin Composite to Lithium Disilicate Ceramic. Dental Materials Journal Vol. 40(5), Pp. 1073-1079.

Vichi, A., Corciolani, G., Carrabba, M., Munoz, A., Louca, C., 2023. Influence of Thickness of Opaque Porcelain and Alloy Color on The Final Color of Porcelain-Fused-to-Metal Restorations. Materials Vol. 16(1), Pp. 1-9.

Vita System, 5-04. VITA Easyshade®

Warreth, A., Elkareimi, Y., 2020. All-Ceramic Restorations: A Review of Literature. The Saudi Dental Journal Vol. 32(8), Pp. 365-372.

Yılmaz, K., Gonuldas, F., Ozturk, C., 2014. The Effect of Repeated Firings on The Color Change of Dental Ceramics using Different Glazing Methods. The Journal of Advanced Prosthodontics Vol. 6(6), Pp. 427.

Copyright (c) 2025 Journal of Vocational Health Studies

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

- The authors agree to transfer the transfer copyright of the article to the Journal of Vocational Health Studies (JVHS) effective if and when the paper is accepted for publication.

- Legal formal aspect of journal publication accessibility refers to Creative Commons Attribution-NonCommercial-ShareAlike (CC BY-NC-SA), implies that publication can be used for non-commercial purposes in its original form.

- Every publications (printed/electronic) are open access for educational purposes, research, and library. Other that the aims mentioned above, editorial board is not responsible for copyright violation.

Journal of Vocational Health Studies is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License