MANUFACTURING TECHNIQUE OF METAL CERAMIC RESTORATION WITH IMPLANT-ABUTMENT AT GINGIVAL RESORPTION CASE

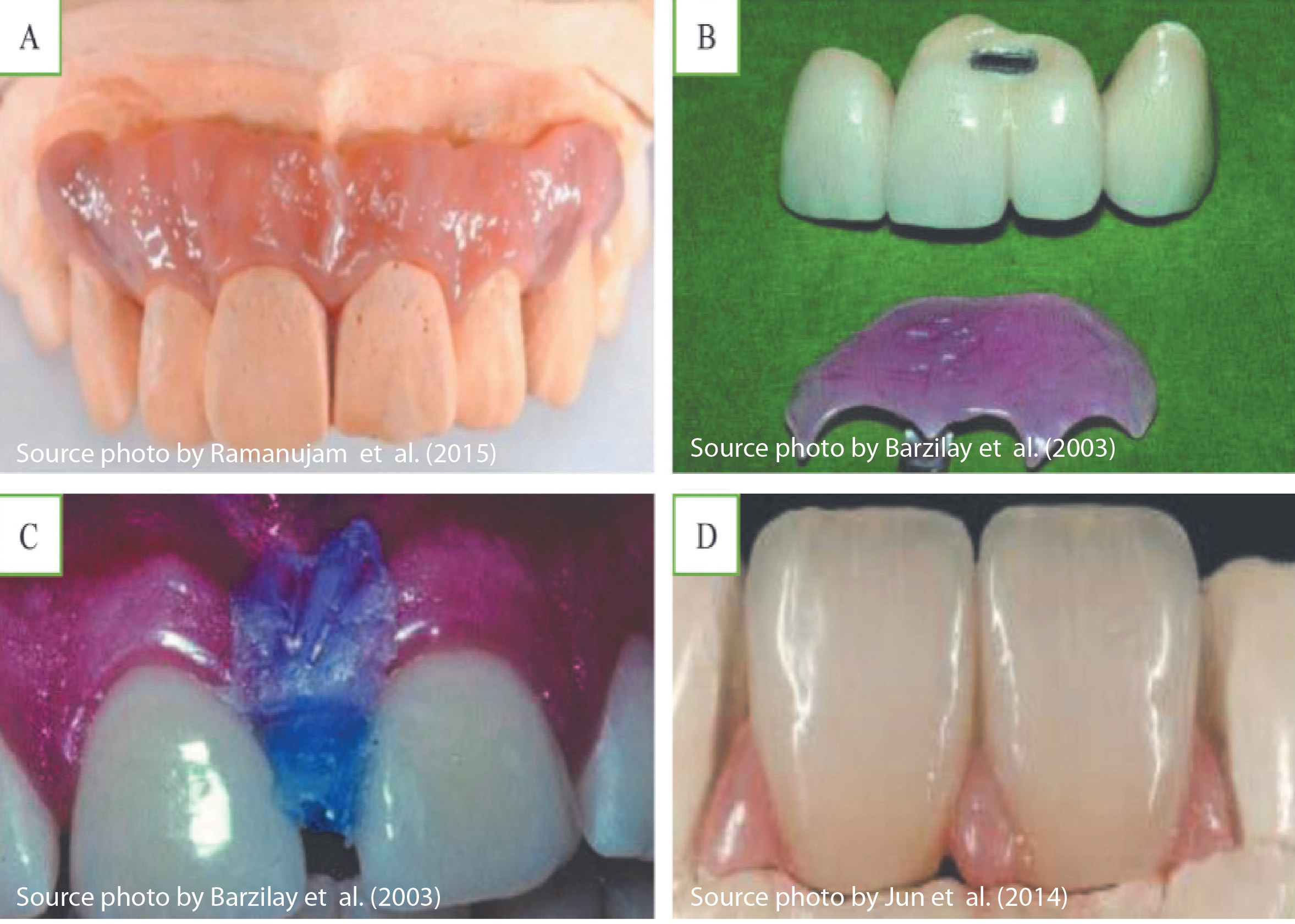

Downloads

Background: The low levels of patient satisfaction and confidence in the restoration of the gingival resorption results in impaired quality of life in both functional and psychosocial aspects. It is necessary to manufacture a dental restoration to restore the mastication, phonetic, and aesthetic functions associated with soft tissue repair. Manufacture of gingiva ceramic restorations which are believed to be an alternative to restore the aesthetic function and harmonization of the patient's teeth. In terms of manufacturing techniques, this restoration has a level of difficulty in achieving a balance between "White aesthetic” and "aesthetic pink”. Purpose: This study aims to provide knowledge to the reader of Manufacturing Technique of Metal Ceramic Restoration with Implant-Abutment at Gingival Resorption Case. Review: Gingiva ceramic restorations can be used to create esthetic implant-supported restorations when bone and gingival tissues are deficient and surgical replacement of such tissues is not possible. Dental technicians should be able to analyze the three-dimensional shapes of gingival anatomy, color, texture, smile components, the balance of the "pink aesthetic” and "white aesthetic”. Conclusion: Manufacturing Technique of Metal Ceramic Restoration with Implant-Abutment at Gingival Resorption Case including the manufacture of metal coping, oxidation, application of opaque coating, application of the first "white aesthetic” ceramics (Opaque Dentine, Dentine, Enamel and transpa on crown coping restorations), Application of opaque gingiva layer, gingival ceramics build-up "pink aesthetics”, first firing, followed by correction build-up, and second firing, and ends with the glazing process.

Barzilay, I., Tamblyn, I. 2003. Gingiva Prostheses-A Review. J Can Assoc Vol. 69(2). Pp.74-8.

Boche, P. 2013. Instructions for use Creation Classic gingival Ceramic. Austria: Creation Willi Geller Int. Pp. 1-11.

Brooks, J.K., Hooper, K.A., Reynolds, M.A. 2003. Formation of mucogingival defects associated with intraoral and perioral piercing. J American Dent Assoc Vol. 134(7) Pp. 837–843.

Carvalho, W., Barboza, E.P., Gouvea, C.V. 2009. The use of porcelain laminate Veneers and a removable gingival prosthesis for a periodontally compromised patient: A clinical report. J ProstDent Vol. 93(4). Pp. 315-317.

Coachman, C., Salama, M., Garber, D., Calamita, M., Salama, H., Cabral, G. 2010. Prosthetic Gingiva Reconstruction in Fixed Partial Restorations Laboratory Procedures and Maintenance. Int J Periodont Restor Dent Vol. 30(1). Pp. 3-13.

Gutter, L., Bleser, U.C. 2009. Implant loading protocols for the partially edentulous esthetic zone. Int J Oral e Maxillofacial Implants Vol. 24(suppl). Pp. 169-79.

Jadhav, V., Khiyani, S. M., Bhoyar, S.C., Mahale, K., Baig, N., Dahiwale, S. 2011. Enhancing Esthetics by Gingival Porcelain. Int. Clinical Dent. Science Vol. 2(4). Pp. 77-9.

Jun, S.K., Klein, H.J., Lagier, L. 2014. The Art and Science of Tissue-Colored Porcelain a Useful Esthetic Alternative. J Cosmetic Dent Vol. 30(2). Pp. 75-86.

Jung, R.E., Holderegger, C., Sailer, I., Khraisat, A., Suter, A., Hammerle, C.H.F. 2008. The Effect of All-Ceramic and Porcelain-Fused-to-Metal on Marginal Peri-implant Soft Tissue Color. Int J Periodontics Restor. Dent Vol. 28. Pp. 357-65.

Karasutisna, S. 2004. Implan Gigi untuk Dokter Gigi Umum (Diagnosis dan Implantasi). Pustaka Unpad. Pp. 1-36.

Kodama, T. 2014. The Management of the pink Tissue Porcelain for the implant Case. Australasian Dent. Pp. 72.

McCracken, M., Ouellette J.P. 2014. BruxZir® Full-Arch Implant Prosthesis: A Case Study. Inclusive Magazine Vol. 5(1). Pp. 12-17.

Naik, N.R., Motwani, B.K., Sahu, S.K., Singh, S. Dani A., Kulkarni, S. 2015. Gingival Porcelain Successful Restoration of Lost Smile. J Dent and Medical Sciences Vol. 14(3). Pp. 18-20.

Nguyen, M. 2005. Superfloss and Floss Threader. Dent Service Cleaning. Available from: http://www.softdental.com/ houston_dentist/dental_superfloss.html. Accessed: July 14th, 2017.

Oktavia, R.N. 2005. Teknik Bedah Peninggian Lingir Alveolar sebagai salah satu Penunjang Keberhasilan di Bidang Prostetik. Medan: Universitas Sumatera Utara. Pp. 1-11.

Petersen, P.E., Bourgeois, D., Ogawa, H., Day, S.E., Ndiaye, C. 2005. The global burden of oral diseases and risks to oral health. Bulletin of the World Health Organization Vol. 83 (9). Pp. 661-9.

Ramanujam, C., Rengasamy, S., Marimuthu, R. 2015. Gingival veneer: A prosthetic solution for the esthetically challenging black triangles: A case series. Indian J Multidisciplinary Dent Vol. 5(1). Pp. 23-36.

Robbins, J.W., Hilton, T. J., Summitt, J.B. 2006. Fundamentals of Operative Dentistry: A Contemporary Approach, 3thEd. Restoration of Endodontically. Quintessing Publishing. Pp. 604-12.

Rosenstiel, Land, Fujimoto. 2001. Contemporary Fixed Pristhodontic. 2nd ed. Mosby Inc. Pp. 254-61.

Shetty, M., Prasad K.D., Shetty, N.H.G., Jaiman, R. 2014. Implant Abutment Connection: BiomechanicalPerspectives. Nitte University J Health Science Vol. 4(2). Pp. 47-53.

Silva, G.R., Roscoe, M.G., Ribeiro, C.P., Mota, A.S., Martin, L.R.M., Soares, C.J. 2012. Impact of Rehabilitation with Metal-Ceramic Restorations on Oral Health-Related Quality of Life. Braz Dent J Vol. 23(4). Pp. 403-408.

Toksavul, S., Turkün, M., Toman, M. 2004. Esthetic Enhancement of Ceramic Crown with Zircomia Dowels and Cores. A Clinical Report.J Prost Dent. Pp. 627-37.

Vailati, F., Belser, C. 2011. Implant-supported Fixed Prostheses with Integrated Artificial Gingiva for the Esthetic Cone the Pink Power Concept. Forum Implantologicum Vol. 7(2). Pp. 108-23.

Wang, J., Lin, J., Gil, M., Silva, J.D.D., Wright, R., Nagai, S.I. 2013. Optical effects of different colors of artificial gingiva on ceramic crowns. J Dent Vol. 41. Pp. 11-17.

ZlataricÌ, D. K., CÌŒelebicÌ, A., PeruzovicÌ, M. V. 2002. The Effect of Removable Partial Dentures on Periodontal Health of Abutment and Non-Abutment Teeth. J Periodontology Vol. 73(2). Pp. 137-44.

Copyright (c) 2019 Journal of Vocational Health Studies

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

- The authors agree to transfer the transfer copyright of the article to the Journal of Vocational Health Studies (JVHS) effective if and when the paper is accepted for publication.

- Legal formal aspect of journal publication accessibility refers to Creative Commons Attribution-NonCommercial-ShareAlike (CC BY-NC-SA), implies that publication can be used for non-commercial purposes in its original form.

- Every publications (printed/electronic) are open access for educational purposes, research, and library. Other that the aims mentioned above, editorial board is not responsible for copyright violation.

Journal of Vocational Health Studies is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License