ADDITION OF RICE HUSK NANOCELLULOSE TO THE IMPACT STRENGTH OF RESIN BASE HEAT CURED

Downloads

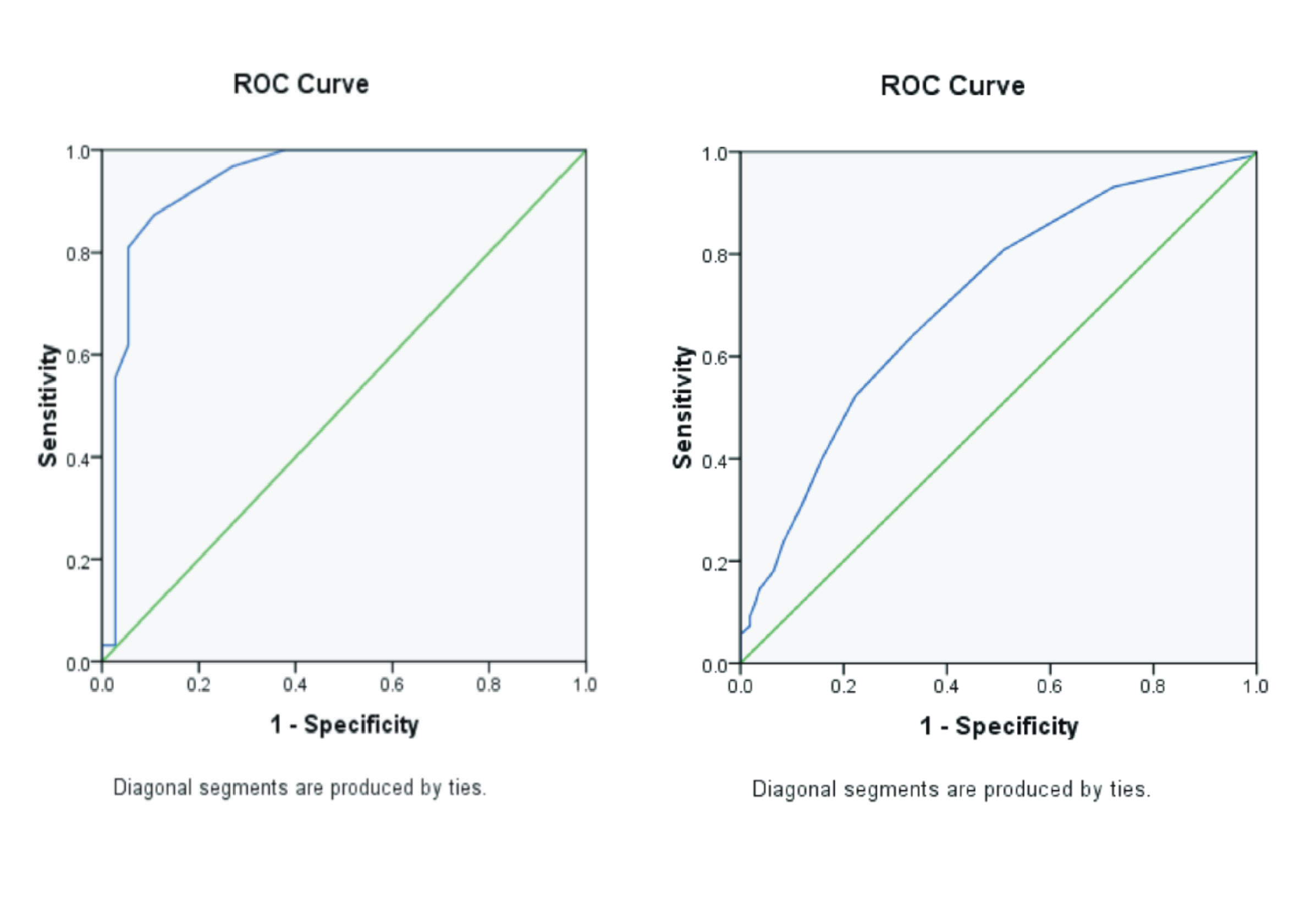

Background: One of the materials for denture bases is heat-cured acrylic resin (PMMA). This material still lacks impact strength as a mechanical strength property. The addition of reinforcing material is known to increase the mechanical strength of PMMA. One of the reinforcing materials added to PMMA is nano cellulose from rice husks, one of the wastes from agricultural products. Purpose: This study aims to determine rice husk nano cellulose's addition to the PMMA denture base's impact strength. Method: The research sample consisted of six groups, each group consisting of 8 samples selected by simple random. The PI, P2, P3, P4, P5, and K groups were PMMA with 1%, 2%, 3%, 4%, 5% nano cellulose, and without nano cellulose. Result: Mean impact strength test results were 41.50 x 10-3 ± 3.891 J / mm2 for P1, 44.13 x 10-3 ± 3,980 J / mm2 for P2, 45.63 x 10-3 ± 4,438 J / mm2 for P3, 46.87 x 10-3 ± 4,824 J / mm2 for P4, 49.12 x 10-3 ± 4.016 J / mm2 for P5 and 36.25 x 10-3 ± 1.982 J / mm2 for K. One way Anova test results with p-value of 0.000 indicates differences in the six groups (p<0.05). Conclusion: This study concludes that the impact strength value of PMMA with the addition of rice husk nano cellulose has increased compared to the control group without the addition of rice husk nano cellulose.

Al-Harbi, F.A., Abdel Halim, M.S., Gad, M.M., Fouda, S.M., Baba, Nadim, Z., Al Rumaih, H.S., Akhtar, S., 2019. Effect of Nanodiamond Addition on Flexural Strength, Impact Strength and Surface Roughness of PMMA Denture Base. J. Prosthodont. 28, 417–425.

Asar, N.V., Albayrak, H., Korkmaz, T., Turkyilmaz, I., 2013. Influence of Various Metal Oxides on Mechanical and Physical Properties of Heat-Cured Polymethyl Methacrylate Denture Base Resins. J. Adv. Prosthodont. 5, 241–247.

Asim, M., Nasir, M., Hashim, R., Sulaiman, O., 2017. Nanocellulose: Preparation Method and Applications. Cellul. Nanofibre Compos. 261–276.

Balos, S., Puskar, T., Potran, M., Markovic, D., Pilic, B., Pavlicevic, J., Kojic, V., 2016. Modulus Elasticity, Flexural Strength and Biocompability of Polymethyl Methacrylate Resin with Low Addition of Nanosilica. Res. Rev. J. Dent. Sci. 4, 26–33.

Budiharjo, A., Wahyuningtyas, E., Sugiatno, E., 2014. Pengaruh Lama Pemanasan Pasca Polimerisasi dengan Microwave terhadap Monomer Sisa dan Kekuatan Transversa pada Reparasi Plat Gigi Tiruan Resin Akrilik. J. Kedokt. Gigi 5, 1–13.

Fahma, F., Hori, N., Iwata, T., Takemura, A., 2012. The Morphology and Properties of Poly (Methyl methacrylate) - Cellulose Nanocomposites Prepared by Immersion Precipitation Method. J. Appl. Polym. Sci. 128, 1–6.

Hamad, Q.A., 2017. Study of The Effect of Nano ceramic Particles on Some Physical Properties of Acrylic Resin. Eng. Technol. J. 35, 124–129.

Ioelovich, M., 2012. Optimal Conditions for Isolation of Nanocrystalline Cellulose Particles. Nanosci. Nanotechnol. 2, 9–13.

Ishak, Z.A.M., 2011. Editorial Corner-A Personal View Rice Husk; Turning Wastes into Walth. eXPRESS Poly. e Xpress Polym. Lett. 5, 569.

J.F., M., A. W. G., W., 2008. Applied Dental Materials, 9 th. ed. EGC, Jakarta.

Jang, D.-E., Lee, J.-Y., Jang, H.-S., Lee, J.-J., Son, M.-K., 2015. Color Stability, Water Sorption and Cytotoxicity of Thermoplastic Acrylic Resin for Non Dental Clasp Denture. J. Adv. Prosthodont. 7, 278–287.

Jatudomi, Gunawan, P.N., Siagian, K. V., 2016. Alasan Pemakaian Gigi Tiruan Lepasan pada Pasien Poliklinik Gigi di BLU RSUP Prof. Dr. R.D. Kandou Manado. J. e-Gigi 4, 40–45.

Johar, N., Ahmad, I., Dufresne, A., 2012. Extraction, Peparation and Characterization of Cellulose Fibres and Nanocrystals. Ind. Crops Prod. 37, 93–99.

K. J., A., Shen, C., R., R., 2012. Phillips Science of Dental Materials, 12 th. ed. Elsevier Science, St. Louis.

Kohli, S., Bhatia, S., 2013. Polyamides in Dentistry. Int. J. Sci. Study 1, 20–25.

Manappalil, J.J., 2015. Basic Dental Materials, 4 th. ed. Jaypee Brothers Medical Publishers, New Delhi.

Pandey, J.K., Kar, K.K., 2015. Handbook of Polymer Nanocomposites, Processing, Performance and Application, 4 th. ed. Springer, London.

Razalie, L.P., 2017. Pengaruh Penambahan Aluminium Oksida terhadap Kekuatan Fleksural dan Impak pada Bahan Basis gigi tiruan Resin Akrilik Heat-cured. Universitas Sumatera Utara.

Riyadi, W., Purwasasmita, B.S., Imam, D.N.A., 2019. Pengaruh Penambahan Nanoselulosa Sekam Padi (O. sativa L.) terhadap Kekuatan Fleksural Bahan Basis Gigi tiruan Resin Akrilik Heat-cured. E-Prodenta J. Dent. 4, 336–342.

Salman, A.D., Jani, G.H., Fatalla, A.A., 2017. Comparative Study of The Effect of IIncorporating SiO2 Nano-particles on Properties of Polymethyl Methacrylate Denture Bases. Biomed. Pharmacol. J. 10, 1525–1535.

Salman, T.A., Khalaf, H.A., 2015. The Influence of Adding of Modified ZrO2 – TiO2 Nanoparticles on Certain Physical and Mechanical Properties of Heat Polymerized Acrylic Resin. J. Baghdad Coll. Dent. 27.

Somani, M.V., Khandelwal, M., Punia, V., Sharma, V., 2019. The Effect of Incorporating Various Reinforcement Materials on Flexural Strength and Impact Strength of Polymethylmethacrylate: A Meta Analysis. J. Indian Prosthodont. Soc. 19, 101–112.

Sulastri, S., Kristianingrum, S., 2010. Berbagai Macam Senyawa Silika: Sintesis, Karakterisasi dan Pemanfaatan. J. Pendidik. Kim. FMIPA.

Talari, F.S., Qujeq, D., Amirian, K., Ramezani, A., 2016. Evaluation the Effect of Cellulose Nanocrystalline Particles on Fleksural Strength and Surface Hardness of Autopolymerized Temporary Fixed Restoration Resin. Int. J. Adv. Biotechnol. Res. 7, 152–160.

Thomas, B., Raj, M.C., K. B., A., M. H., R., Joy, J., Moores, A., Drisko, G.L., Sanchez, C., 2018. Nanocellulose, A Versatile Green Platform: From Biosources to Materials and Their Applications. ACS 118, 11575–11625.

Copyright (c) 2021 Journal of Vocational Health Studies

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

- The authors agree to transfer the transfer copyright of the article to the Journal of Vocational Health Studies (JVHS) effective if and when the paper is accepted for publication.

- Legal formal aspect of journal publication accessibility refers to Creative Commons Attribution-NonCommercial-ShareAlike (CC BY-NC-SA), implies that publication can be used for non-commercial purposes in its original form.

- Every publications (printed/electronic) are open access for educational purposes, research, and library. Other that the aims mentioned above, editorial board is not responsible for copyright violation.

Journal of Vocational Health Studies is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License