IDENTIFICATION AND RISK CONTROL OF THE HACCP SYSTEM IMPLEMENTATION IN THE PASTEURIZED CRAB PRODUCTION PROCESS

Downloads

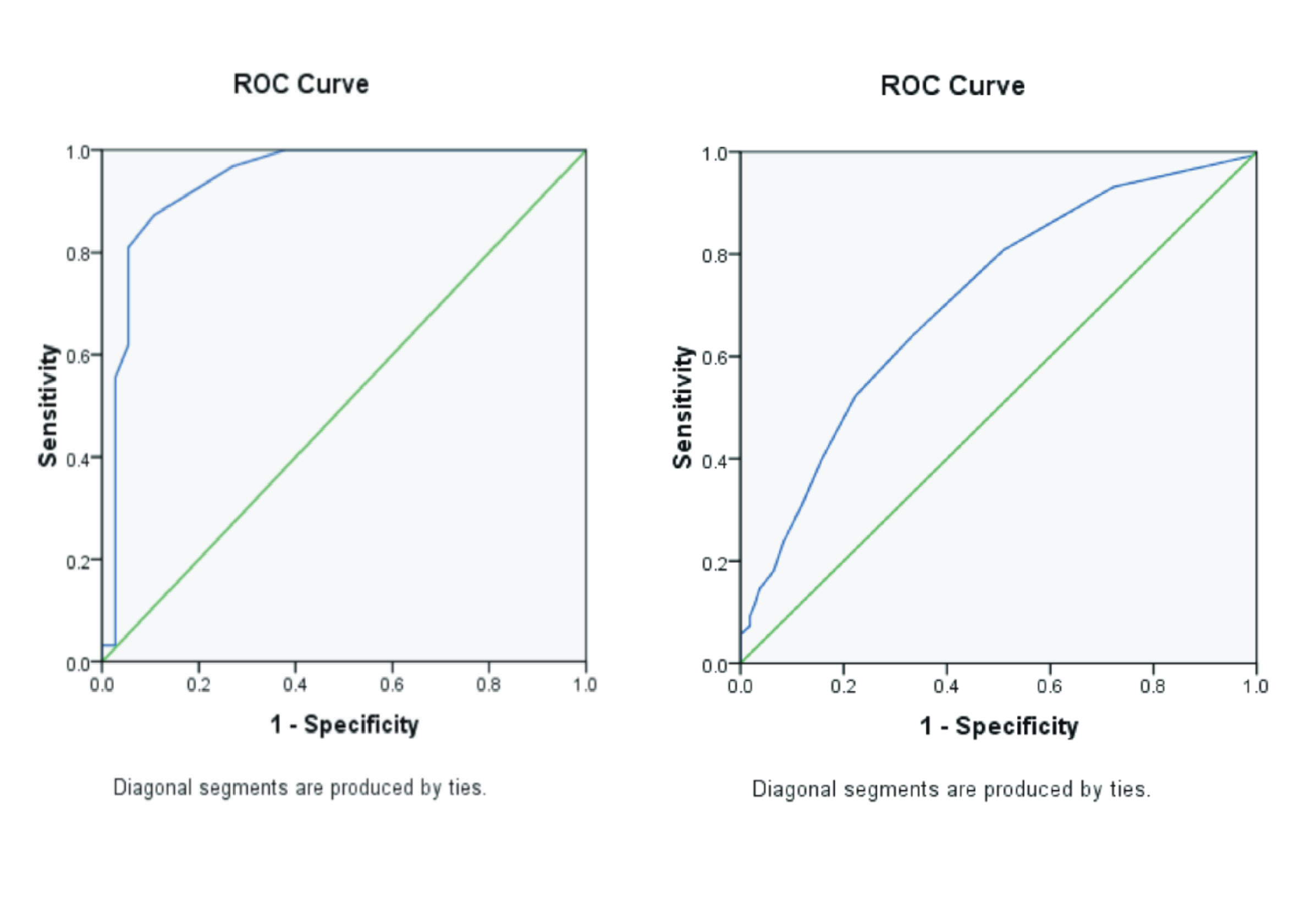

Background: In the production process, small accidents often occur between fellow workers in the production area, such as workers colliding with each other during the transfer process from one process to the next which causes the product to spill and workers fall, causing injury. PT. XYZ is a company engaged in the seafood industry, especially canning crabs. The company's production process applies a Good Manufacturing Practice (GMP) system with 12 work areas and 80% of the process is still done manually. Purpose: The purpose of this study is to identify risks and control the implementation of the HACCP system in the crab canning industry using the HAZOP method. Method: This type of research is a descriptive study, using the HAZOP (Hazard and Operability) method. The research was carried out at 12 nodes, namely receiving, checking aroma, sorting, mixing and filling, metal detecting, weighing, seaming, pasteurization, chilling, packing, and sanitation.Result: The results showed 4 risk ratings, namely low, medium, high, and extreme risk based on 8 sources of potential hazards. The biggest risk that is extreme is in node seaming. Conclusion: Based on processing data, 8 sources of potential hazards that can occur in the pasteurized crab meat production room. The recommendations given are to implement elimination, reduction, engineering control, administrative control, Personal Protective Equipment, work attitude improvement, and OHS training.

Amelia, O., 2018. Evaluasi dan Penerapan Sistem Penjamin Mutu Produksi "Value Added” Rajungan (portunus pelagius) di Pabrik Pengolahan Rajungan Provinsi Lampung. Universitas Bandar Lampung.

Aulia, A., 2020. The Application of HACCP (Hazard Analysis Critical Control Point) in Food Production Department. J. Sos. Hum. Terap. 2, Pp. 101-106.

Boruthnaban, A.J., Handoko, F., W., J.H.G., 2021. Perbaikan Kinerja Identifikasi Potensi Bahaya untuk Mengurangi Risiko Kecelakaan Kerja dengan Pendekatan Hazard Identification, Risk Assesment and Risk Control (HIRARC) di PT. XYZ. J. Valtech 4, Pp. 49-56.

Budak, Åž.Ö., 2017. A Model for Implementation of HACCP System for Prevention and Control of Mycotoxins during The Production of Red Dried Chili Pepper. Food Sci. Technol. 37, Pp. 24-29.

Budiawan, E., 2016. Analisa Penerapan HACCP (Hazard Analysis Critical Control Point) pada Produk Susu di PT. Netania Kasih Karunia dengan Identifikasi Potensi Bahaya dan Pemantauan Critical Control Point. Universitas Brawijaya.

Carrascosa, C., Millán, R., Saavedra, P., Jaber, J.R., Raposo, A., Sanjuan, E., 2015. Identification of The Risk Factors Associated with Cheese Production to Implement the Hazard Analysis and Critical Control Points (HACCP) Systems on Cheese Farms. J. Dairy Sci. 99, Pp. 2606-2616.

Cheraghi, M., Eslami, A., Baladeh, Khakzad, N., 2019. A Fuzzy Multi-Attribute HAZOP Technique (FMA-HAZOP): Application to Gas Wellhead Facilities. Saf. Sci. 114, Pp. 12-22.

Drago, V., Ratao, I., 2019. HACCP Methodology Implementation in A Goat Cheese Production Process of A Small Company. In: Monteiro, J., Silva, A.J., Mortal, A., Aníbal, J., Silva, M.M. da, Oliveira, M., Sousa, N. (Eds.), INCREaSE 2019, Proceedings of the 2nd International Congress on Engineering and Sustainability in the XXI Century. Springer International Publishing, Portugal, p. Pp. 213-222.

Gautam, R.K., Venugopal, V., 2021. Electron Beam Irradiation to Control Biohazards in Seafood. Food Control 130, Pp. 108320.

Hati, S.W., R., I., 2016. Analisis Faktor-Faktor yang Mempengaruhi Produktivitas Tenaga Kerja Wanita Bagian Operator Produksi pada Industri Manufaktur di Kawasan Batamindo Batam. In: Applied Business and Engineering Conference Batam, 16-17 September 2015. Politeknik Negeri Batam dan Politeknik Caltex Riau, Batam. Pp. 202-217.

Hati, S.W., Wahyuni, W., 2016. The Effect of The Application of Work Safety and Health to Awareness of SOP (Standard Operating Procedure) on Employee Bulk (Subcaintractor) Contruction in The Company XYZ Batam. In: Proceedings International Conference on Accounting, Management Economics and Social Sciences (ICAMESS) April 30. Jakarta. Pp. 516-530.

Ishteyaque, S., Jabeen, S., Abro, S.H., Ghani, A.A., 2019. Hazard and Operability Study of Gas Exploration Field Located in Pakistan. Sindh Univ. Res. J. (Science Ser. 51, Pp.189-194.

Kim, H.-J., Lee, D.-S., Lee, J.-M., Kim, Y.-M., Shin, I.-S., 2018. Bacteriological Hazard Analysis in Minimally Processed Shellfish Products Purchased from Korean Seafood Retail Outlets. Korean J. Fish. Aquat. Sci. 51, Pp. 121-126.

Li, W., 2020. An Unpredictable Hazard in Lithium-ion Batteries from Transition Metal Ions: Dissolution from Cathodes, Deposition on Anodes and Elimination Strategies. J. Electrochem. Soc. 167, Pp. 090514.

Lim, C.H., Lam, H.L., Ng, W.P.Q., 2018. A Novel HAZOP Approach for Literature Review on Biomass Supply Chain Optimisation Model. Energy 146, Pp. 13-25.

Mariana, R.R., Hidayati, L., Soekopitojo, S., 2019. Implementing the HACCP System to The Production of Bakso Malang-Indonesia. J. Culin. Sci. Technol. 17, Pp. 291-312.

Mawan, M., Suherman, I., 2019. Analisis Penerapan Sistem HACCP (Hazard Analysis Critical Control Point) pada Pabrik Tahu Tradisional di Daerah Purwakarta. J. Kalibarasi - Karya Lintas Ilmu Bid. Rekayasa Arsit. 2, Pp. 1-15.

Mohammed, A.J., Bostan, K., 2018. Potential Seafood Safety Hazard: Vibro vulnificus. Aydın Gastronomy. Aydin Gastron. 2, Pp. 61-72.

Pandelaki, C.D., 2016. Identifikasi Bahaya pada Proses Pengalengan Rajungan (portunus pelagicus) dalam Penerapan HACCP (Hazard Analysis Critical Control Point) di PT. Sumber Mina Bahari Rembang-Jawa Tengah. Universitas Airlangga.

Putri, N.T., Rhamadani, A., Wisnel, W., 2019. Designing Food Safety Standards in Beef Jerky Productions Process with the Application of Hazard Analysis Critical Control Point (HACCP). Nutr. Food Sci. 50, Pp. 333-347.

Rachmawati, A., 2021. The Correlation between Nurses "Knowledge Regarding Patient Safety and Nurses” Behaviours in Drug Management. South East Nurs. Res. 3, Pp. 51-58.

Suhardi, B., Laksono, P.W., Rohani, J.M., Ayu, V.E.A., 2018. Analysis of The Potential Hazard Identification and Risk Assessment (HIRA) and Hazard Operability Study (HAZOP). Int. J. Eng. Technol. 7, Pp. 1-7.

Suryani, F., 2018. Penerapan Metode Diagram Sebab Akibat (Fish Bone Diagram) dan FMEA (Failure Mode and Effect) dalam Menganalisa Risiko Kecelakaan Kerja di PT. Pertamina Talisman Jambi Merang. J. Ind. Serv. 3.

Svinarky, I., Sudianto, S., Zulkiul, Z., Mutholib, A., 2020. Sistem Manajemen K3. Batam Publisher.

Syron, L.N., Lucas, D.L., Bovbjerg, V.E., Case, S., Kincl, L., 2018. Occupational Traumatic Injuries among Offshore Seafood Processors in Alaska, 2010-2015. J. Safety Res. 66, Pp.169-178.

Copyright (c) 2021 Journal of Vocational Health Studies

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

- The authors agree to transfer the transfer copyright of the article to the Journal of Vocational Health Studies (JVHS) effective if and when the paper is accepted for publication.

- Legal formal aspect of journal publication accessibility refers to Creative Commons Attribution-NonCommercial-ShareAlike (CC BY-NC-SA), implies that publication can be used for non-commercial purposes in its original form.

- Every publications (printed/electronic) are open access for educational purposes, research, and library. Other that the aims mentioned above, editorial board is not responsible for copyright violation.

Journal of Vocational Health Studies is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License