APPLICATION OF THE BEHAVIORALLY ANCHORED RATING SCALE (BARS) IN ASSESSING EMPLOYEES’ OCCUPATIONAL SAFETY AND HEALTH SITUATIONAL AWARENESS

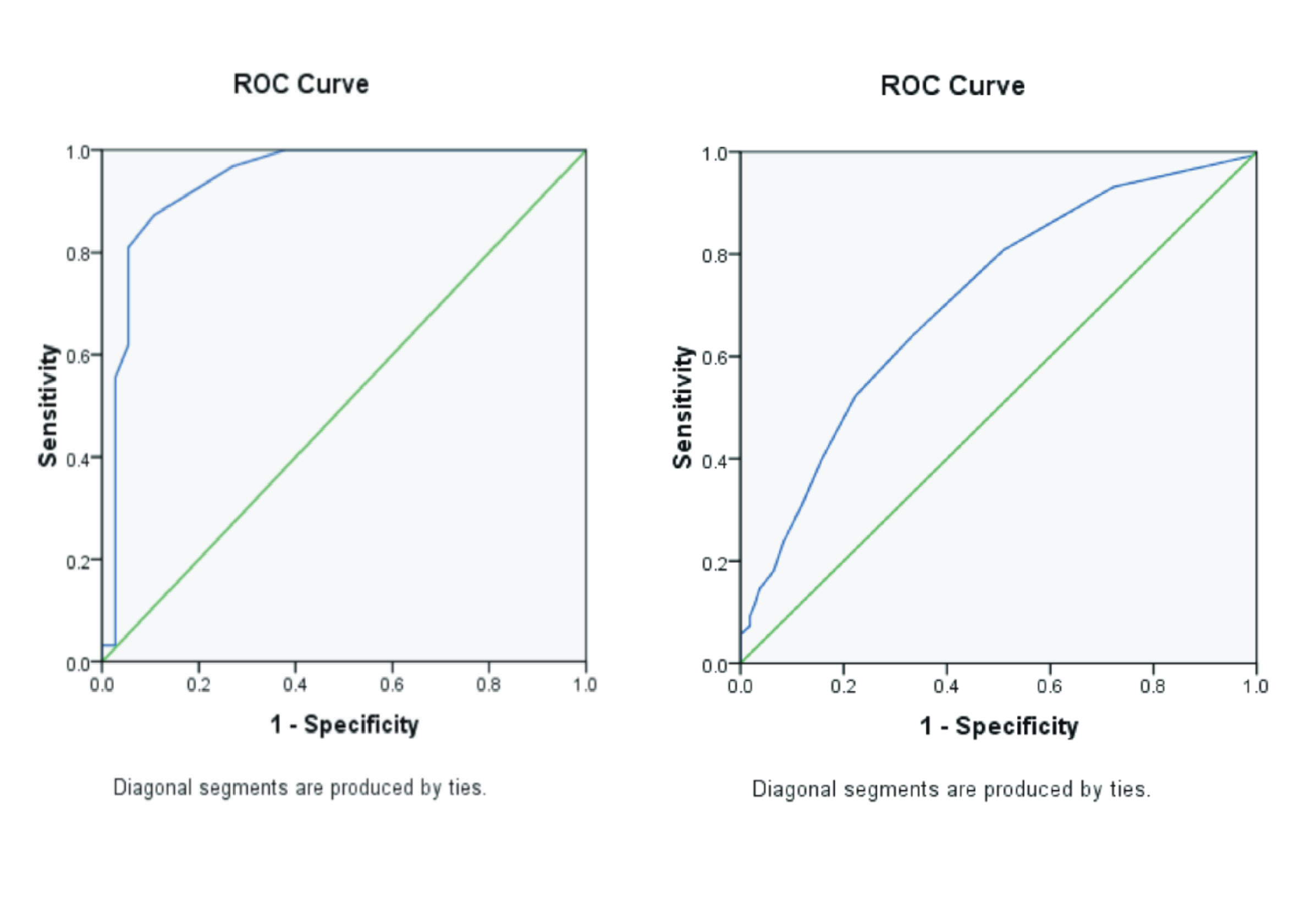

Background: In 2017, at PT. XY, the average Frequency Rate (FR) was 4.68 accidents for every one million working hours, while the average Severity Rate (SR) was 336.16 lost workdays per one million work hours. These indicators reveal that 264 accidents and 18.983 working days lost during 56.469.736 working hours throughout the current year. Purpose: This research aims to determine the level of alertness among workers and investigate their behavior in carrying out tasks at the PT. XY factory. Method: Worker data were collected using sampling techniques and analyzed employing the Behaviorally Anchored Rating Scale (BARS) method to provide potential dangers and worker behavior in the PT. XY factory section. The research approach applied was quantitative, collecting data through the distribution of 44 questionnaires to workers in that section. Result: The potential hazards occurring in the PT. XY factory were attributed to workers’ lack of attention to Situational Awareness (SA) while doing work, where in the PT. XY factory section there are three processes, namely first press, second press, and filtration stage. The results of the confidence levels in the office section of the PT. XY factory showed actual accuracy and perceived accuracy values of 46.67% and 86.67%, respectively. In the process section, workers exhibited actual accuracy and perceived accuracy values of 42.85% and 84.28%, while in the maintenance section, the actual accuracy value was 44.81% and the perceived accuracy was 84.90%. Conclusion: Based on data analysis, office workers showed the highest level of alertness (65.00%), followed by maintenance workers (63.67%), while workers in the process section showed the lowest alertness level (63.00%).

Introduction

In a company, it is very important to consider health and safety at work to avoid accidents that might occur. The importance of paying attention to the situation and location of the workplace, or situational awareness, before doing work, needs to be emphasized. In the production process, the working conditions or place must always be in a safe condition in terms of the environment, the condition of the production machines used, and the Personal Protective Equipment (PPE) provided to the employees. Providing PPE to employees must follow basic procedures, and they must be informed about the dangers posed and trained on how to use and care for them properly(Sepang et al., 2013). Apart from that, work discipline influences work safety, where one indicator of work discipline is always obeying existing regulations. This means that workers who apply work discipline will minimize the occurrence of work accidents, usually caused by the worker’s negligence(Saputra & Mahaputra, 2022).

One effort to protect workers is by implementing Occupational Health and Safety (OHS) programs, such as carrying out training. Training serves as a forum for employees to improve their skills. In this context, training has a very broad scope related to the work process, including skills acquired from the learning process and field practice. Job training activities provide benefits to both employees and companies, in the form of expertise and skills which become valuable assets for the company(Susilo & Kasmir, 2022). Work safety indicates a condition of being safe from suffering, damage, or loss in the workplace. Meanwhile, occupational health refers to a condition that is free from physical, mental, emotional, or pain disorders caused by the work environment(Khair et al., 2021).

Occupational Health and Safety(OHS) is a form of protection for employees when carrying out their duties, aimed at preventing from potential risks such as work accidents or work-related illnesses. This also aims to create a comfortable and safe work environment, with the hope of increasing employee productivity(Rosento et al., 2021). Companies must pay attention to the implementation of OHS at work to minimize undesirable incidents related to the risk of work accidents, which can result in losses for the company(Tambunan et al., 2021). Every activity in the workplace has potential dangers that can cause work accidents. Work accidents are undesirable and often unexpected events that can cause loss of time, property, or life(Hamdani et al., 2018). Achieving zero accidents is one of the goals of OHS(Panjaitan, 2017).

In general, there are two factors that can cause work accidents, namely humans and the environment(Pangkey et al., 2023). Lack of caution or awareness of the situation, as well as unintentional acts that violate work safety regulations, are human factors. Meanwhile, unsafe actions from the work environment include issues with machinery and work equipment, as well as environmental factors(Suminar et al., 2015).

The Ministry of Manpower reported 157.313 work accident cases throughout 2018, from 2015 to 2018, data recorded nationally by the Social Security Agency for Employment (BPJS) showed 252 cases in 2015, 243 cases in 2016, and 241 cases in 2017. Although there was a decrease in the number of work accidents compared to the previous year, it was still relatively high. Occupational health and safety are important issues in operational processes in the industrial sector. Every year, the number of work-related accidents in Indonesia is still relatively high(Hasanuddin, 2018).

PT. XY Tarjun unit, is one of the largest companies in Indonesia engaged in agribusiness and food. The process of producing cooking oil has risk and hazard factors that can interfere with the safety and health of PT. XY Tarjun’s workforce. As a product maker, the company is expected to maintain and improve product quality, providing a strong reason to increase worker productivity(Rauf et al., 2003). However, poor conditions in the work environment, worker negligence, operational errors, and not using PPE are causes of workplace accidents. Implementing daily OHS inspections to ensure the use of complete PPE and strengthening management supervision of workers who do not wear PPE are risk control measures that can be implemented to mitigate workplace accidents(Waruwu & Yuamita, 2016). This issue is further emphasized by the high frequency and severity of accidents in the work environment. Data show that the average Frequency Rate (FR) is 4.68 accidents per one million working hours, and the Severity Rate (SR) reaches 336.16 lost working days per one million working hours. Over 56.469.736 working hours in one year, 264 accidents occurred with 18.983 lost working days(Organization, 2023). Therefore, it is necessary to apply situational awareness as a strategy to reduce the risk of accidents and increase work safety. Situational awareness is key to workers’ responses to potential hazards and to preventing accidents in the work environment. This study aims to determine the level of situational alertness among workers and analyze their behavior in carrying out tasks at the PT. XY using the BARS method.

Material and Method

This research has been ethically tested and received an ethical certificate from the Ethics Commission of the Faculty of Industrial Technology, Universitas Muslim Indonesia on June 23th, 2021 No: 017/B.06/TI/FTI-UMI/XII/2022. This research focused on workers in the KCP factory section, specifically those in the position of office, process, and maintenance sections. The main variables of interest were

Evita, S.N., Zusnita Muizu, W.O., Wahyu Atmojo, R.T., 2017. Penilaian Kinerja Karyawan dengan Menggunakan Metode Behaviorally Anchor Rating Scale dan Management by Objectives (Studi Kasus pada PT Qwords Company International). PEKBIS Vol. 9(1), Pp. 18-32.

Fang, Y., Cho, Y.K., Durso, F., Seo, J., 2018. Assessment of Operator’s Situation Awareness for Smart Operation of Mobile Cranes. Automation in Construction Vol. 85, Pp. 65-75.

Febriyanti, B.M., Faslah, R., 2013. Hubungan antara Beban Kerja dengan Kinerja pada Karyawan Balai Permasyarakatan Kelas I Jakarta Selatan (Bapas) di Jakarta Timur. Jurnal Pendidikan Ekonomi dan Bisnis (JPEB) Vol. 1(2), Pp. 104-116.

Hamdani, M.Z., Rudyarti, E., Phuspa, S.M., 2018. The Correlation of Personal Protective Equipment Socialization Toward the Changing of Occupational Safety and Health Behavior of Musical Instrument Craftsmen. Journal of Vocational Health Studies Vol. 2(1), Pp. 14-19.

Hasanuddin, D, 2018. Accurate Formula for Reducing Work Accident Rates. ISafety Magazine.

International Labour Organization (ILO) (2023). Safety and Health at Work: ILO Global Report 2023. Geneva: ILO.

Ivascu, L., Sarfraz, M., Mohsin, M., Naseem, S., Ozturk, I., 2021. The Causes of Occupational Accidents and Injuries in Romanian Firms: An Application of the Johansen Cointegration and Granger Causality Test. International Journal of Environmental Research and Public Health Vol. 18(14), Pp. 7634.

Khair, H., R.Sabrina, Batubara, R.W., 2021. Effect of Occupational Safety, Health (K3) and Leadership Style on Employee Work Productivity Mediated by Discipline in Operations PTPN IV Balimbingan. Legal Brief Vol. 11(1), Pp. 1450-1459.

Klieger, D., Kell, H., Rikoon, S., Burkander, K., Bochenek, J., Shore, J., 2018. Development of the Behaviorally Anchored Rating Scales for The Skills Demonstration and Progression Guide: Development of BARS for The Skills Demonstration and Progression Guide. ETS Research Report Series Vol. 1.

Kustiadi, O., 2018. Perancangan Penilaian Kinerja dengan Metode Behaviorally Anchor Rating Scale di PT. Zeno Alumi Indonesia. Jurnal Inkofar Vol. 1(1), Pp. 279606.

Laurila-Pant, M., Pihlajamäki, M., Lanki, A., Lehikoinen, A., 2023. A Protocol for Analysing The Role of Shared Situational Awareness and Decision-Making in Cooperative Disaster Simulations. International Journal of Disaster Risk Reduction Vol. 86, Pp. 103544.

Lusiana, Uray. 2012. Application of Calibration Curve, Accuracy and Precision Control Chart as Internal Quality Control in COD Testing in Wastewater. Biopropal Industri Vol. 3(1), Pp. 1-8.

Machfudiyanto, R.A., Latief, Y., Robert, 2019. Critical Success Factors to Improve Safety Culture on Construction Project in Indonesia. IOP Conf. Ser.: Earth Environ. Sci. Vol. 258(1), Pp. 012016.

Munir, A., Aved, A., Blasch, E., 2022. Situational Awareness: Techniques, Challenges, and Prospects. AI Vol. 3(1), Pp. 55-77.

Pangkey, S.J.I., Lengkong, V.P.K., Saerang, R.T., 2023. Analisis Penerapan Kesehatan dan Keselamatan Kerja (K3) sebagai Upaya Pencegahan Kecelakaan Kerja di PT. PLN (Persero) UP3 Manado. Jurnal EMBA : Jurnal Riset Ekonomi, Manajemen, Bisnis dan Akuntansi Vol. 11(4), Pp, 200-211.

Panjaitan, N., 2017. Bahaya Kerja Pengolahan RSS (Ribbed Smoke Sheet) menggunakan Metode Hazard Identification dan Risk Assessment di PT. PQR. Jurnal Sistem Teknik Industri Vol. 19(2), Pp. 50-57.

Paskarini, I., Rahman, F.S., Dwiyanti, E., Mulyono, 2019. Occupational Accident in Industry: The Causes, Type and Impact on Workers in Sidoarjo, Indonesia. International Journal of Modern Trends in Engineering and Research (IJMTER) Vol. 6(2), Pp. 9-12.

Prasetya, T.A.E., Mukhadiroh, L., Fitrahanjani, C., 2022. Contributing Factors in Informal Worker Performance: A Cross-Sectional Study in An Agro-Fish Market in Lamongan, East Java, Indonesia. Nusantara Science and Technology Proceedings Pp. 41-49.

Prawito, A., Yuniar, Desrianty, A. 2014. Measurement of The Level of Alertness of Young Car Drivers in The City of Bandung using Quantitative Analysis of Situational Awareness (QUASA). Integra Design, Vol. 1(4), Pp. 169-179

Rauf, N., Padhil, A., Yulyanda, A., 2003. Analysis of The Influence of Price and Product Performance, on The Decision of Heavy Equipment Customer Buying Excavator Products ABC PT. XYZ. Journal of Optimization in Industrial Engineering Vol. 16(1), Pp. 141-145.

Rosento, R., Yulistria, R., Handayani, E., Nursanty, S., 2021. Pengaruh Keselamatan dan Kesehatan Kerja (K3) Terhadap Produktivitas Kerja Karyawan. Swabumi Vol, 9(2), Pp. 147-158.

Saleh, L., Russeng, S., Tajuddin, I., Hardi Yanti, I., Syafitri, N., Yusbud, M., Rahmadani, Y., 2022. The Development of a Work Stress Model for Air Traffic Controllers in Indonesia. Kesmas Jurnal Kesehatan Masyarakat Nasional Vol. 17(1), Pp. 40-47.

Saputra, F., Mahaputra, M.R., 2022. Building Occupational Safety and Health (K3): Analysis of the Work Environment and Work Discipline. Journal of Law, Politic and Humanities Vol. 2(3), Pp. 105-114.

Sepang, B.A.W., Tjakra, J., Langi, J.E.C., Walangitan, D.R., 2013. Manajemen Risiko Keselamatan dan Kesehatan Kerja (K3) pada Proyek Pembangunan Ruko Orlens Fashion Manado. Jurnal Sipil Statik Vol. 1(4), Pp. 282-288.

Suminar, A.C., Mukzam, M.D., Ruhana, I., 2015. Pengaruh Gaya Kepemimpinan dan Lingkungan Kerja terhadap Kinerja. Jurnal Administrasi Bisnis (JAB) Vol. 26(2), Pp. 1-10.

Susilo, R., Kasmir, K., 2022. The Effect of Job Training, Work Motivation, Occupational Health and Safety (K3) on Employee Performance at Cibitung Medika Hospital. Journal of Social Research Vol. 2(1), Pp. 234-243.

Tambunan, H.N., Nazaruddin, Sadalia, I., 2021. Analysis of Knowledge, Implementation and Monitoring of K3 on Occupational Health and Safety Management System (SMK3) at Pt. Mujur Lestari Labuhan Batu Selatan. International Journal of Research and Review Vol. 8(12), Pp. 404-410.

Taufik, T., Fithri, P., Prathama, Y., 2016. Perancangan Aplikasi Sistem Penilaian Kinerja Karyawan dengan Metode MBO dan BARS (Studi Kasus PLTA Maninjau). Jurnal Optimasi Sistem Industri Vol. 13(2), Pp. 760.

Trapsilawati, F., Herliansyah, M.K., Nugraheni, A.S.A.N.S., Fatikasari, M.P., Tissamodie, G., 2020. EEG-Based Analysis of Air Traffic Conflict: Investigating Controllers’ Situation Awareness, Stress Level and Brain Activity during Conflict Resolution. The Journal of Navigation Vol. 73(3), Pp. 678-696.

Waruwu, S., Yuamita, F., 2016. Analisis Faktor Kesehatan dan Keselamatan Kerja (K3) yang Signifikan Mempengaruhi Kecelakaan Kerja pada Proyek Pembangunan Apartement Student Castle. Spektrum Industri Vol. 14(1), Pp. 63-78.

Copyright (c) 2025 Journal of Vocational Health Studies

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

- The authors agree to transfer the transfer copyright of the article to the Journal of Vocational Health Studies (JVHS) effective if and when the paper is accepted for publication.

- Legal formal aspect of journal publication accessibility refers to Creative Commons Attribution-NonCommercial-ShareAlike (CC BY-NC-SA), implies that publication can be used for non-commercial purposes in its original form.

- Every publications (printed/electronic) are open access for educational purposes, research, and library. Other that the aims mentioned above, editorial board is not responsible for copyright violation.

Journal of Vocational Health Studies is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License