THE EFFECT OF PREHEATING AT 39o AND 60o ON COMPRESSION STRENGTH OF BULK-FILL COMPOSITE RESIN

Background: The incremental placement technique for composite resin may lead to bond failures and air entrapment between resin layers. Bulk-fill composite resin, which can be applied to cavities depths of up to 4 - 5 mm, is expected to have good compressive strength so that it can resemble natural tooth structures. Purpose: This study aimed to evaluate the effect of preheating on the compression strength of bulk-fill composite resins at 39oC and 60oC. Method: This research type was a laboratory experiment employing a post-test control group design. A total of 27 cylindrical bulk-fill composite resin specimens were divided into three groups: group 1 was preheated at 39oC, group 2 at 60oC, and group 3 served as the control group. The samples were then immersed in distilled water and stored in an incubator at 37oC for 48 hours. Compressive strength test was measured using a Universal Testing Machine. Result: One-way ANOVA statistical test showed that there were significant differences in the three groups (p-value < 0.05). A post-hoc Bonferroni test was carried out to compare between groups and indicated a significant difference between the 600 preheated group and the control group. Conclusion: Preheating at 39oC and 60oC affects the compression strength of bulk-fill composite resin.

Introduction

Composite resin is one of the materials that is most frequently utilized in dental restoration operations due to its excellent durability and aesthetic quality(Cheng et al., 2022). Composite resin is typically applied in layers, with a maximum thickness of 2 mm for each layer. However, this incremental technique is time-consuming and may result in interlayer gaps, increasing the risk of bond failure and air entrapment between resin layers(Hatrick, 2016);(Yudistian, 2022). A restorative substance called bulk-fill composite resin was developed to overcome these shortcomings. Cavities up to 4 - 5 mm thick can be filled using bulk-fill composite resin in a single polymerization step(Composition of Dental Resin-Based Composites for Direct Restorations, 2018). This is possible due to the deep cure depth, low polymerization shrinkage, and higher translucency level of bulk-fill composite resin, which facilitates easier light transmission during the polymerization process(Haugen et al., 2020). Designed primarily for posterior tooth restorations, bulk-fill composite resins are expected to withstand masticatory loads. Compressive strength—often referred to as compression strength—is therefore a critical property, as it reflects the material’s ability to resemble natural teeth(Akarsu & Aktuğ Karademir, 2019).

According to(Bhat et al., 2019), a decent restoration material should have a compression strength range of 300 – 380 MPa, which is comparable to that of enamel and dentin. According to(Sakaguchi et al., 2016), composite resins typically have compressive strength values between 200 to 450 MPa. The bulk-fill method yields an average compression strength of 191.65 MPa for composite resin, according to a study by(Mundung et al., 2018). Similar studies by(Mofidi et al., 2020)revealed that bulk-fill composite resin had an average compression strength of 250.5 MPa. The findings from both trials indicated that the compressive strength of bulk-fill composite resins was inadequate. When compared to enamel and dentin, the strength of the composite resins was much lower, so it has the potential to break easily if subjected to strong pressure from chewing.

The process of polymerization can be influenced by various things.(Imam et al., 2020)reported that raising the temperature of the resin optimizes polymerization, leading to a higher degree of conversion and increased polymer cross-linking, which enhances material solidification. Preheating has therefore been suggested as a method to improve the material's mechanical and physical properties, including surface hardness, microleakage, and compression strength(AlShaafi, 2017).

Several studies have demonstrated how preheating affects the characteristics of composite resin. According to research by(Khaerani, 2022), bulk-fill composite resin's surface hardness can be considerably raised by preheating it to 39°C. Similarly,(Ramadhan, 2021)found that bulk-fill composite resin microleakage can be minimized by preheating at 60°C. However, this study’s findings do not address the difference between 39°C and 60°C in terms of the bulk-fill composite resin’s compression strength. Therefore, the purpose of this study is to know the effect of preheating bulk-fill composite resin at 39°C and 60°C on compression strength.

Material and Method

This laboratory experimental study employed a post-test control group design. The specimens were cylindrical bulk-fill composite resin. In this study using the Federer method, the number of samples used was calculated to be nine samples for each group. However, due to outliers identified during data analysis, the final sample size was adjusted to eight specimens per group. In total, there were three treatment groups. As the control group, (1) Group 1 comprises composite resin that was preheated to 39°C, (2) Group 2 comprises composite resin that was preheated to 60°C, and (3) Group 3 consists of composite resin that was not preheated

A cylindrical polyurethane mold was prepared with a thickness of 2 mm and a diameter of 5 mm. 1 composite resin syringe (Tetric® N-Ceram Bulk-Fill, Liechtenstein) was preheated to 39°C for group 1 and 60°C for group 2 in an incubator (Memmert, Germany) for 30 minutes, then taken out and the temperature checked using a digital thermometer. Unpreheated samples were used for group 3. However, temperature checks were still carried out at ambient temperature. The composite was inserted into the mold, then compacted using a cement stopper as soon as possible to avoid a significant temperature reduction after being removed from the incubator. The surface of the composite resin was coated with a Mylar strip and then pressed with an object glass. Polymerization was carried out using a light cure (Woodpecker LED-C, China) for 10 seconds and the distance between the tip unit and the composite was 1 mm (right above the glass object). The sample was released from the mold, then soaked in a plastic jar containing distilled water and stored in an incubator at 37°C for 48 hours. After being kept in the incubator for 48 hours, the jar containing the sample was taken out and dried with tissue paper. A Universal Testing Machine (Controlab/TN20MD, France) was used to evaluate the compression strength of the sample at a pace of 1 mm per minute until it shattered. The amount of compression strength obtained was calculated and documented.

Result

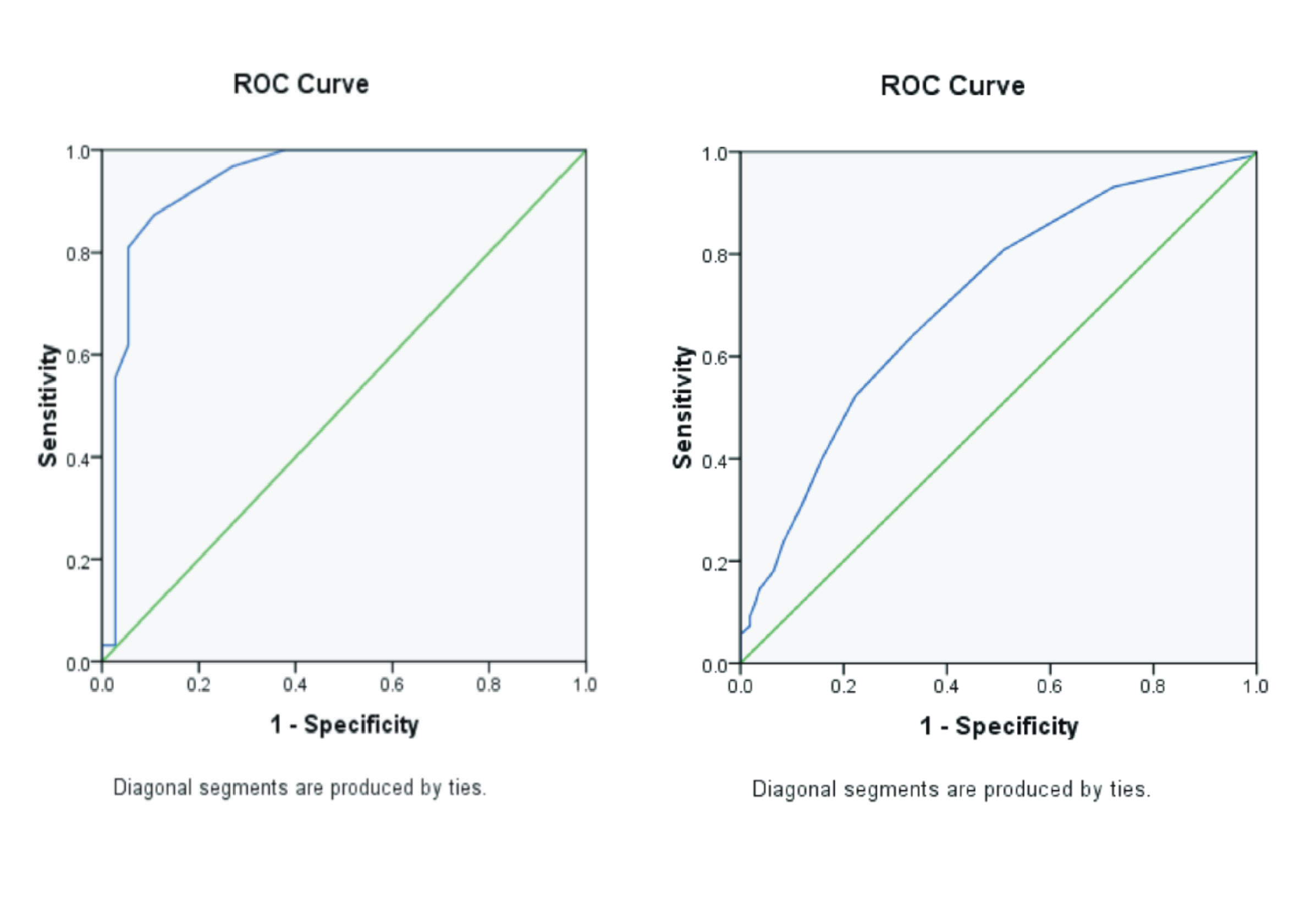

The test results of the compression strength in each group can be seen inFigure 1. Based on the test results inFigure 1, the standard deviation of group 3 indicated poor data distribution due to the existence of values that are too extreme or outliers in group 3. It was necessary to trim the three groups by

Akarsu, S., Aktuğ Karademir, S., 2019. Influence of Bulk-Fill Composites, Polimerization Modes, and Remaining Dentin Thickness on Intrapulpal Temperature Rise. BioMed Research International Vol. 2019, Pp. 4250284.

Allorerung, J., Anindita, P.S., Gunawan, P.N., 2015. Uji Kekerasan Resin Komposit Aktivasi Sinar dengan Berbagai Jarak Penyinaran. e-GiGi Vol. 3(2), Pp. 444-448.

AlShaafi, M.M., 2017. Factors Affecting Polymerization of Resin-Based Composites: A Literature Review. The Saudi Dental Journal Vol. 29(2), Pp. 48-58.

Andari, E.S., Wulandari, E., Robin, D.M.C., 2014. Efek Larutan Kopi Robusta terhadap Kekuatan Tekan Resin Komposit Nanofiller. Stomatognatic - Jurnal Kedokteran Gigi Vol. 11(1), Pp. 6-11.

Arora, V., Arora, P., Shammrani, A.A., Fahmi, M.K., 2017. Devices & Methods for Pre-Heating/Pre-Warming Dental Resin Composites: A Critical Appraisal. International Journal of Oral Health and Medical Research Vol. 4(2), Pp. 52-55.

Bhat, V.S., Nandish, B., K, J., 2019. Science of Dental Materials with Clinical Applications, Edition 3rd. ed. CBS Publishers & Distributors.

Cheng, L., Zhang, L., Yue, L., Ling, J., Fan, M., Yang, D., Huang, Z., Niu, Y., Liu, J., Zhao, J., Li, Y., Guo, B., Chen, Z., Zhou, X., 2022. Expert Consensus on Dental Caries Management. International Journal of Oral Science Vol. 14(1), Pp. 17.

Elkaffas, A.A., Eltoukhy, R.I., Elnegoly, S.A., Mahmoud, S.H., 2019. The Effect of Preheating Resin Composites on Surface Hardness: A Systematic Review and Meta-Analysis. Restorative Dentistry & Endodontics Vol. 44(4), Pp. e41.

Harahap, M., 2018. Elektroforesis: Analisis Elektronika Terhadap Biokimia Genetika. CIRCUIT: Jurnal Ilmiah Pendidikan Teknik Elektro Vol. 2(1), Pp. 21-26.

Hatrick, C.D., 2016. Dental Materials Clinical Applications for Dental Assistans and Dental Hygienist, Edition 3rd. ed. St. Louis, Missouri : Elsevier, United States, America.

Haugen, H.J., Marovic, D., Par, M., Thieu, M.K.L., Reseland, J.E., Johnsen, G.F., 2020. Bulk Fill Composites Have Similar Performance to Conventional Dental Composites. International Journal of Molecular Sciences Vol. 21(14), Pp. 5136.

Imam, D.N.A., Dwiandhono, I., Kurniawan, A.A., 2020. Pengaruh Preheating dan Heat Treatment terhadap Kekuatan Kompresi Resin Komposit Nanohibrida. E-Prodenta Journal of Dentistry Vol. 4(2), Pp. 330-335.

Ivoclar, 2014. Tetric® N-Ceram.

Khaerani, L., 2022. Pengaruh Suhu Penyimpanan dan Preheating terhadap Kekerasan Permukaan Resin Komposit Bulk-Fill (Skripsi). Universitas Indonesia, Jakarta.

Mofidi, Maryam, Zanguei, E., Shadman, N., Salehi, H., 2020. Compressive Strength of Bulk Fill and Conventional Nano-Hybrid Composite Resins: An In Vitro Study. Journal Dental Sch Summer Vol. 8(3), Pp. 110-114.

Mundung, C., Wowor, V.N.S., Wicaksono, D.A., 2018. Uji Perbandingan Kekuatan Kompresi Tumpatan Resin Komposit dengan Teknik Incremental Horizontal dan Teknik Bulk. e-GiGi Vol. 6(2), Pp. 56-60.

Poubel, D., Zanon, A., Almeida, J., Rezende, L., Garcia, F., 2022. Composite Resin Preheating Techniques for Cementation of Indirect Restorations. International Journal of Biomaterials Vol. 2022, Pp. 1-10.

Ramadhan, A.G., 2021. Perbedaan Tingkat Kebocoran Mikro Preheating Resin Komposit Bulk-Fill pada Suhu 50o dan 60o. (Skripsi). Universitas Jenderal Soedirman, Purwolerto.

Randolph, L.D., Palin, W.M., Leprince, J.G., 2018. Composition of Dental Resin-Based Composites for Direct Restorations. In: Miletic, V. (Ed.), Dental Composite Materials for Direct Restorations. Springer International Publishing, Cham, Pp. 11–24.

Razibi, N.D., Nahzi, M.Y.I., Puspitasari, D., 2017. Perbandingan Jarak Penyinaran dan Ketebalan Bahan terhadap Kekerasan Permukaan Resin Komposit Tipe Bulk Fil. Jurnal Kedokteran Gigi Vol. 2(2), Pp. 211-214.

Sakaguchi, R.L., Ferracane, J., Powers, J.M., 2016. Craig’s Restorative Dental Materials, Edition 14th. ed. Mosby.

Shen, C., Rawls, R., F, J., Esquivel-Upshaw, 2021. Phillips’ Science of Dental Materials, Edition 13 th. ed.

Tauböck, T.T., Tarle, Z., Marovic, D., Attin, T., 2015. Pre-Heating of High Viscosity Bulk-Fill Resin Composites: Effects on Shrinkage Force and Monomer Conversion. Journal of Dentistry Vol. 43(11), Pp. 1358-1364.

Van Ende, A., De Munck, J., Lise, D.P., Van Meerbeek, B., 2017. Bulk-Fill Composites: A Review of The Current Literature. The Journal of Adhesive Dentistry Vol. 19(2), Pp. 95-109.

Yudistian, I., 2022. Bulk Fill Composite Resin Restoration Techniques Replace Incremental Techniques. Interdental Jurnal Kedokteran Gigi (IJKG) Vol. 17(1), Pp. 9-14.

Copyright (c) 2025 Journal of Vocational Health Studies

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

- The authors agree to transfer the transfer copyright of the article to the Journal of Vocational Health Studies (JVHS) effective if and when the paper is accepted for publication.

- Legal formal aspect of journal publication accessibility refers to Creative Commons Attribution-NonCommercial-ShareAlike (CC BY-NC-SA), implies that publication can be used for non-commercial purposes in its original form.

- Every publications (printed/electronic) are open access for educational purposes, research, and library. Other that the aims mentioned above, editorial board is not responsible for copyright violation.

Journal of Vocational Health Studies is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License